With

a great deal of pleading I was able to spend a week learning what it was

to make paper. It was cold, grueling, and totally delightful.

With

a great deal of pleading I was able to spend a week learning what it was

to make paper. It was cold, grueling, and totally delightful.

Karasuyama translates, I think, to Crow Mountain. It is one of the most idylic place on the earth. The village is full of old houses with thached roofs. The streets are narrow and the river runs in a series of small falls and rapids past the town. At the summer festival there is a lot of theather, a lot of paper (of course), and lots of grilled fish from traps in the river.

With

a great deal of pleading I was able to spend a week learning what it was

to make paper. It was cold, grueling, and totally delightful.

With

a great deal of pleading I was able to spend a week learning what it was

to make paper. It was cold, grueling, and totally delightful.

Water Filter; water comes off the mountain into this tank where the sediment settles out. The clean water is then used in the papermaking.

What

some people refer to as Japanese rice paper is not really made of rice.

The hand made paper of Japan is made from mulberry bark.

What

some people refer to as Japanese rice paper is not really made of rice.

The hand made paper of Japan is made from mulberry bark.

I started my batch of paper by

cooking the bark in lye for 12 hours. Since it was a wood fire I

had to tend it for that entire time. We started at 3 in the afternood

and I got to bed shortly after 3 in the morning.

A lot of time to look at the

stars above crow mountain in the cold spring air. The hot lye dissolves

any organic impurities in the bark. This is the top view of the cooker,

the fire is below.

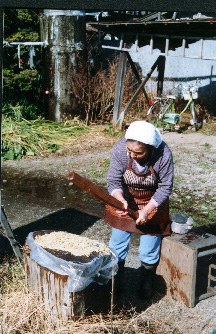

After

the cooked bark cooled I got to beat it with a stick for 4 hours only stopping

to take these posed pictures. The obasan and my sensei didn't really

beat it much, they were just posing for photos. It's backbreaking

and I found out after I finished that now days they use a mechanical beater.

After

the cooked bark cooled I got to beat it with a stick for 4 hours only stopping

to take these posed pictures. The obasan and my sensei didn't really

beat it much, they were just posing for photos. It's backbreaking

and I found out after I finished that now days they use a mechanical beater.

The result after a severe beating

is pulp.

There

is a little canal running through the cleaning room. It's a wood

trough with water from the tank running through it. Elderly women

sit for hours at a time washing the pulp to remove any impurities.

In the winter the water numbs the hands in seconds. But the women

laugh and tease me as I fumble at the job. The chat all morning,

stop for tea breaks and lunch and then work til four, cheerful throughtout.

There

is a little canal running through the cleaning room. It's a wood

trough with water from the tank running through it. Elderly women

sit for hours at a time washing the pulp to remove any impurities.

In the winter the water numbs the hands in seconds. But the women

laugh and tease me as I fumble at the job. The chat all morning,

stop for tea breaks and lunch and then work til four, cheerful throughtout.

Finally

the paper goes into a bug tub (in the background here) with a lot of water.

Finally

the paper goes into a bug tub (in the background here) with a lot of water.

You gather the paper/water mixture

in a kind of screen, then lift it out of the water

shaking and moving the screen

in a delicate dance to make sure the pulp spreads evenly.

Once the water is all gone you

have a very wet sheet of paper. You carefull peel it off

and put it in a stack of other

sheets alternating with felt.

The

stack then goes into a hydraulic press and the rest of the water is squeezed

out. At this point the fibers a locked and it really is paper.

The

stack then goes into a hydraulic press and the rest of the water is squeezed

out. At this point the fibers a locked and it really is paper.

After it comes out of the press

you seperate the sheets and put them on a drying rack, or for the lesser

grades (or sometimes when it's raining out) on a large metal plate, heated

by a wood oven.

While I was there they got a

request from a very rich man to have his emblem cast in a single sheet

of paper about 6' x 6'. He intended it for shoji. The whole

crew has to shake the large screen togeather in unison. They had

a really hard time peeling off the sheet once it was formed.